Desiccant Dryers 10-800 CFM

Desiccant Dryers protect compressed air lines from oil, water, rust, and freezing. The FDS Desiccant Dryer from PneuTech combines superior dew points with high efficiency and delivers

high-quality, dry compressed air with comparatively low cost compared to other desiccant options. Offers a lower initial investment, less maintenance, and reduced energy consumption.

The low dew point of -40°F produces ultra-dry air, eliminates re-work and scrap in processes that are hyper-sensitive to moisture, and avoids expensive downtime. The spin-off desiccant cartridges make maintenance simple and easy. The SFD cartridge design eliminates damaging downstream desiccant dust.

The robust construction of the PneuTech Desiccant Dryer does not require frequent cleaning, and can be used outdoors. Optional non-electric model can be used in remote locations. View features & benefits

| Model | Max HP | Max CFM | Control Type | NPT (in) | Voltage | Dryers per Row | # of rows | Weight Per Row | price |

|---|---|---|---|---|---|---|---|---|---|

| FDS-10-116 | 3 | 10 | MLT | 3.4 | 115/1/60 | 1 | 1 | 42 | |

| FDS-27-116 | 7.5 | 27 | MLT | 3.4 | 115/1/60 | 1 | 1 | 46 | |

| FDS-40-116 | 10 | 40 | MLT | 3.4 | 115/1/60 | 1 | 1 | 46 | |

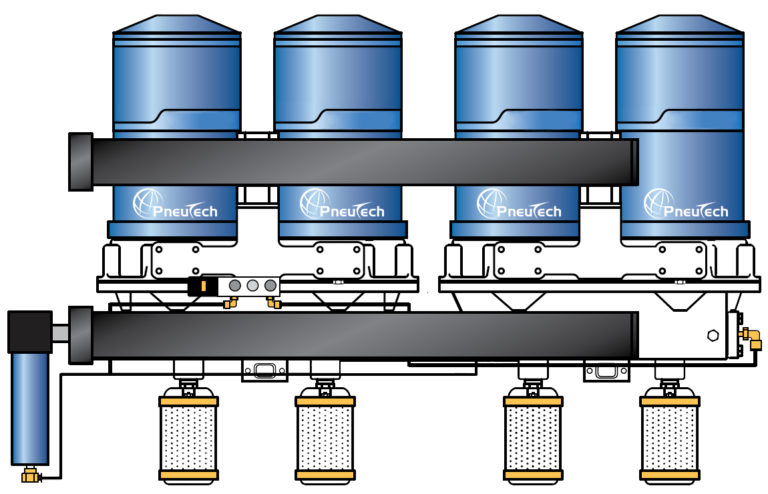

| FDS-80-116 | 20 | 80 | MLT | 1 1/2 | 115/1/60 | 2 | 1 | 120 | |

| FDS-120-116 | 30 | 120 | MLT | 1 1/2 | 115/1/60 | 3 | 1 | 170 | |

| FDS-200-116 | 40 | 200 | PLC | 1 1/2 | 115/1/60 | 3 | 1 | 170 | |

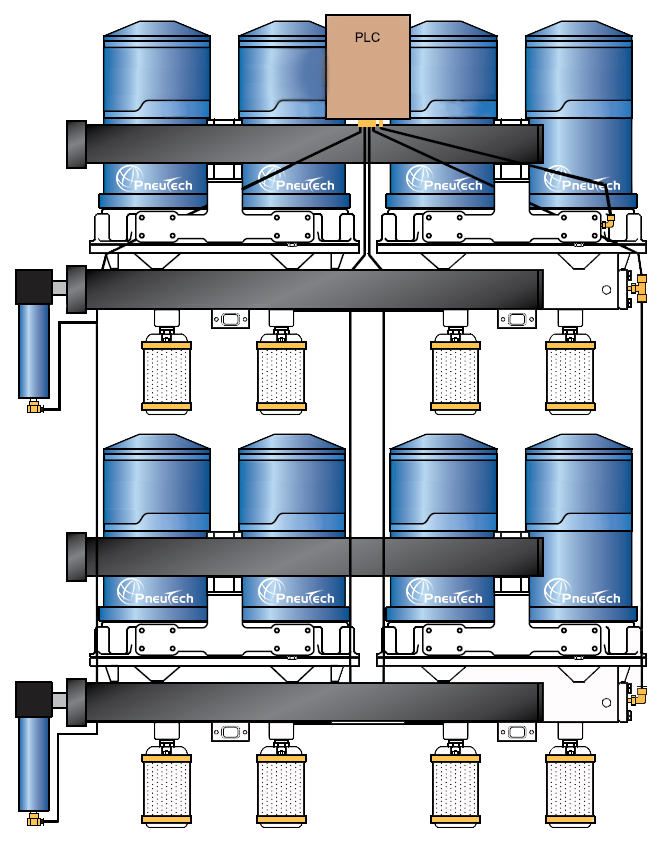

| FDS-240-116 | 50 | 240 | PLC | 1 1/2 | 115/1/60 | 2 | 2 | 120 x 2 | |

| FDS-400-116 | 75 | 400 | PLC | 1 1/2 | 115/1/60 | 3 | 2 | 170 x 2 | |

| FDS-600-116 | 125 | 600 | PLC | 1 1/2 | 115/1/60 | 3 | 3 | 170 x 3 | |

| FDS-800-116 | 150 | 800 | PLC | 1 1/2 | 115/1/60 | 3 | 4 | 170 x 4 |

Features and Benefits

Two Options in Logic Control

- MLT: Micro Logic Controller

- PLC: Programmed Logic Controller

- Requires 110VAC and is in a NEMA4 rated enclosure

MLT: Micro Logic Controller

Alternates compressed air flow and regenerates cartridges at 2-minute intervals.